Laser Power Screed WS-940C

In stock

WS-940C 3.0m Ride On Self Levelling Concrete Laser Machine. Hire or buy.

This ride-on laser controlled screed accurately levels concrete whilst applying consolidatary vibration. This hydraulically controlled laser guided screed offers enhanced productivity which means you can level concrete on large jobs quickly and accurately.

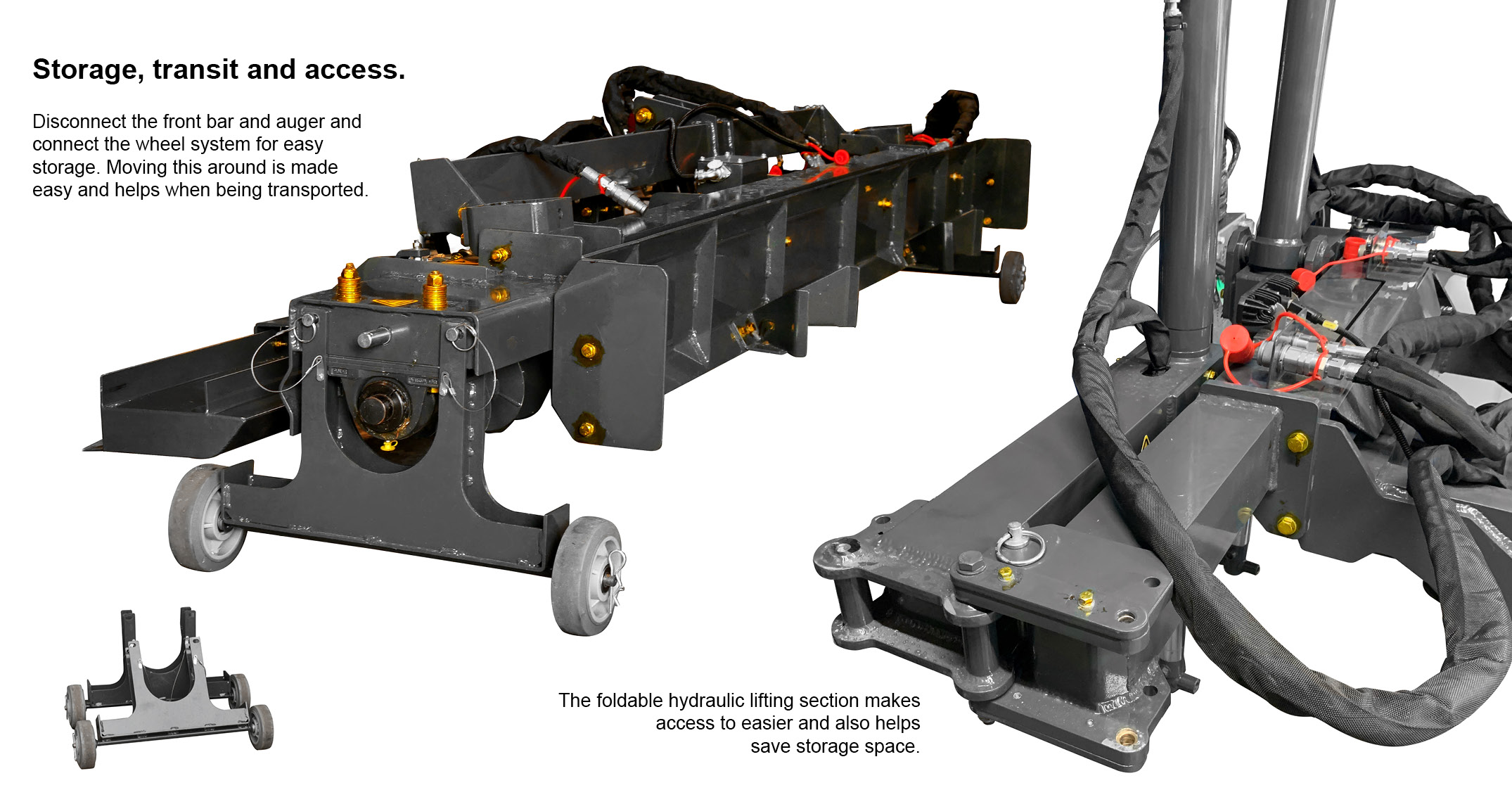

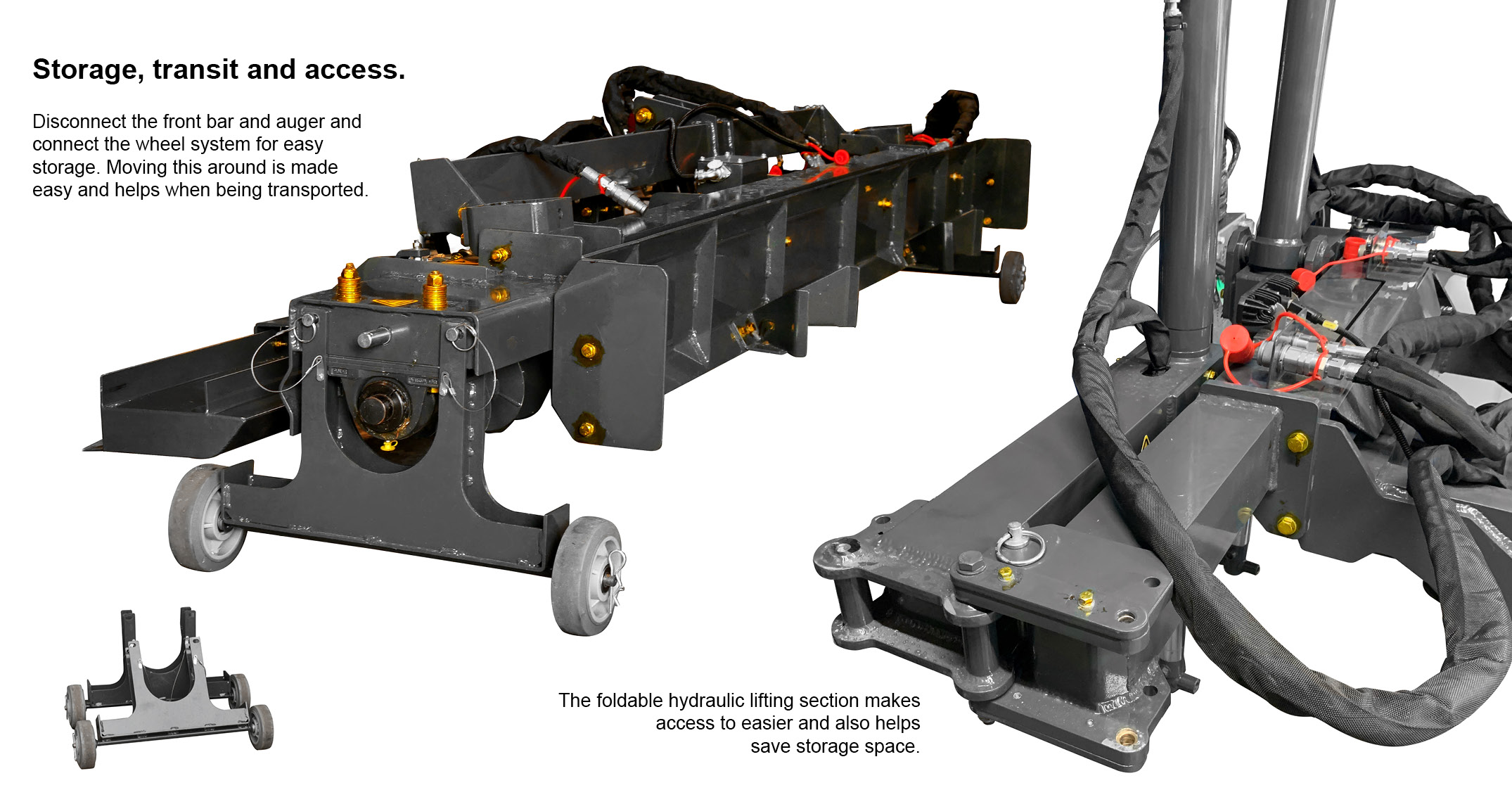

The WS-940C has been manufactured to provide easy entry to job sites due to the foldable elevation beam that gives the WS-940C a narrow profile when not levelling the concrete, this feature also facilitates major advantages during transportation and in storage. Another feature is the off-set screed head which reduces overlapping on each pass. The detachable grade head comes with a set of wheels that can be quickly attached to allow this front section to be removed and moved about.

The WS-940C is 3D ready and can be coupled to Leica positional sensors and control equipment to screed the work area off to a predefine 3D profile.

Scroll down to learn more about the features and benefits of the laser power screed. Click the download icon below to learn more.

Advantages of laser screed technology include very high precision, capable of controlling levels to the millimeter. Work speed is much faster than traditional methods, capable of screeding hundreds of square meters per hour, and reducing labour use by up to 60% compared to traditional screeding methods.

Using a laser controlled screed system can also work well in areas with reinforcement steel or obstacles because it can adjust levels precisely and avoid collisions with various obstructions. Laser controlled screeds also helps concrete achieve more uniform density through precisely controlled screeding processes.

Laser Controlled screeds also help to reduce risk of work corrections because high precision reduces chances of errors, eliminating time and costs for repairs or redoing work. It can also work in various environments, whether narrow or wide areas, with or without obstacles. Another advantage is reduced environmental impact because highly efficient work reduces fuel use and pollution emissions. Appropriate use of concrete without waste also helps reduce material loss.

Engine Type:Honda GX690

Characteristic:Air-Cooled 4 Stroke, 2 Cylinder

Power:18.4KW/25HP

Fuel:Petrol

Paving Thickness:50-200mm

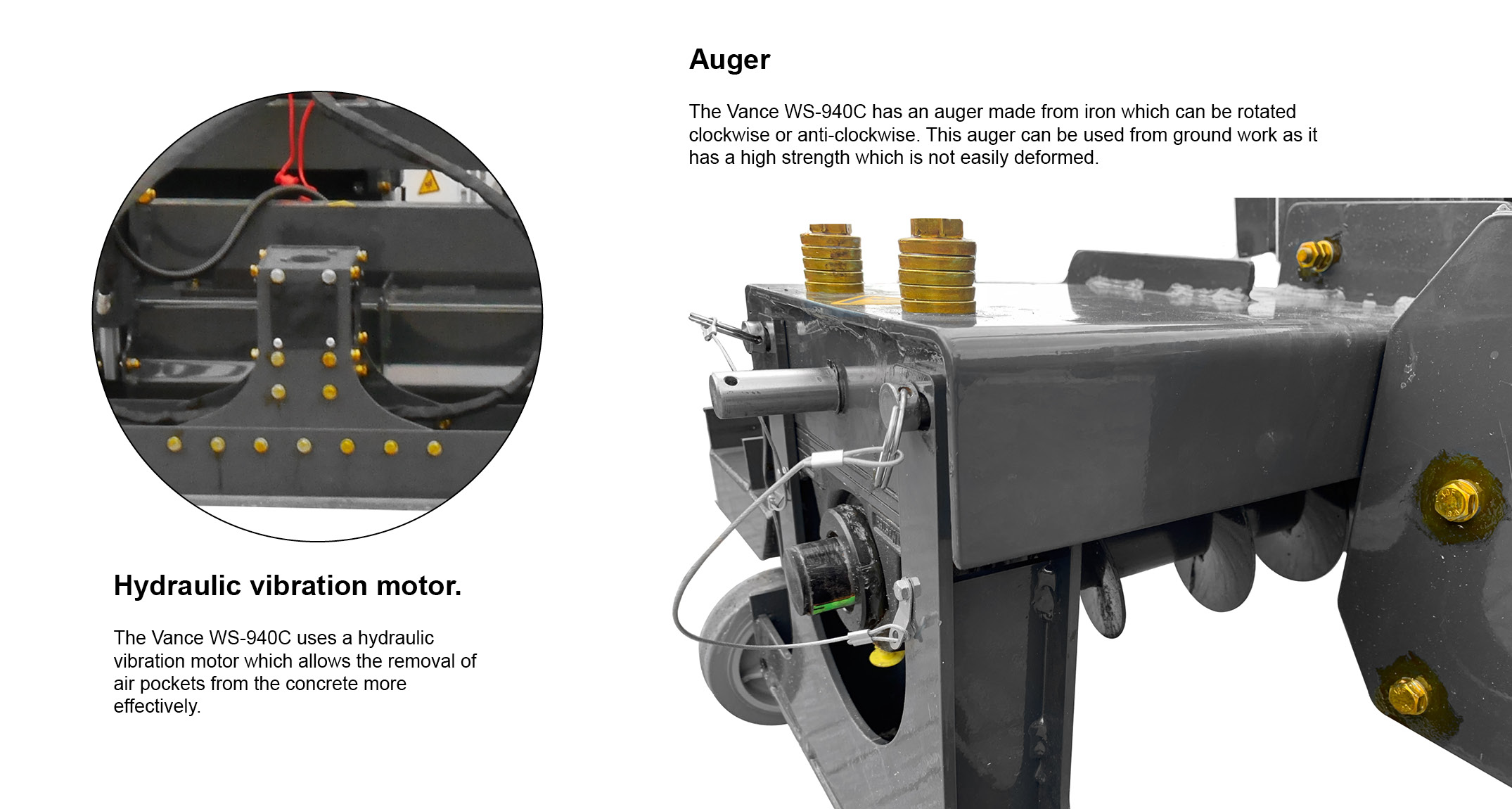

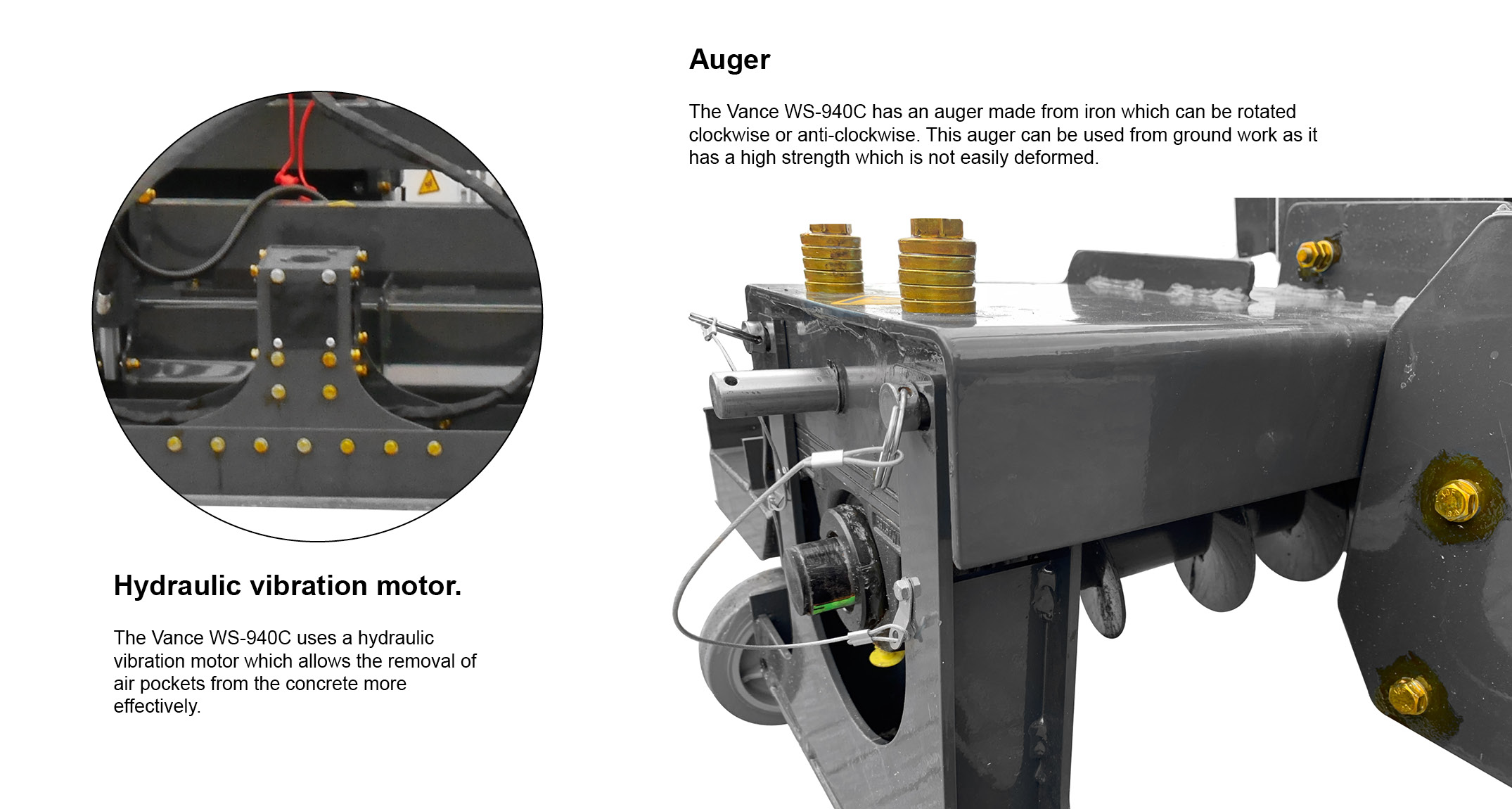

Vibrating System:Hydraulic Vibration

Excitation Force:200-900N

Vibration Frequency:50-60HZ

Walking Speed:2.7 mph

Mini Turning Radius:2300mm

Steering Angle:L 40° R 36°

![Gator Alloy Edging Trowels [Arris Trowels]](https://www.speedcrete.co.uk/media/catalog/product/cache/9d40f6b1fe79103b79daf274578364cd/h/a/hand-edger-gatorloy-web-speedcrete3.jpg)